HIGH CHROME CAST GRINDING MEDIA - BALLS & CYLPEBS & BALLPEBS & MINIBALLS

FTRsteel is cooperating with the world's biggest Hi Cr cast grinding media manufacturer. Our company keeps significant amount of stock in Turkey in order to ship in a very short time to domestic and export markets. These kind of high chrome balls/grinding media are mainly and extensively used in Cement and Mining industries as well as mineral and additive grinding processes. The cast high chrome grinding media for Cement or Mining applications are in the range of 5% to 32% Cr content that are defined according to grinding process operating parameters and customer expectations.

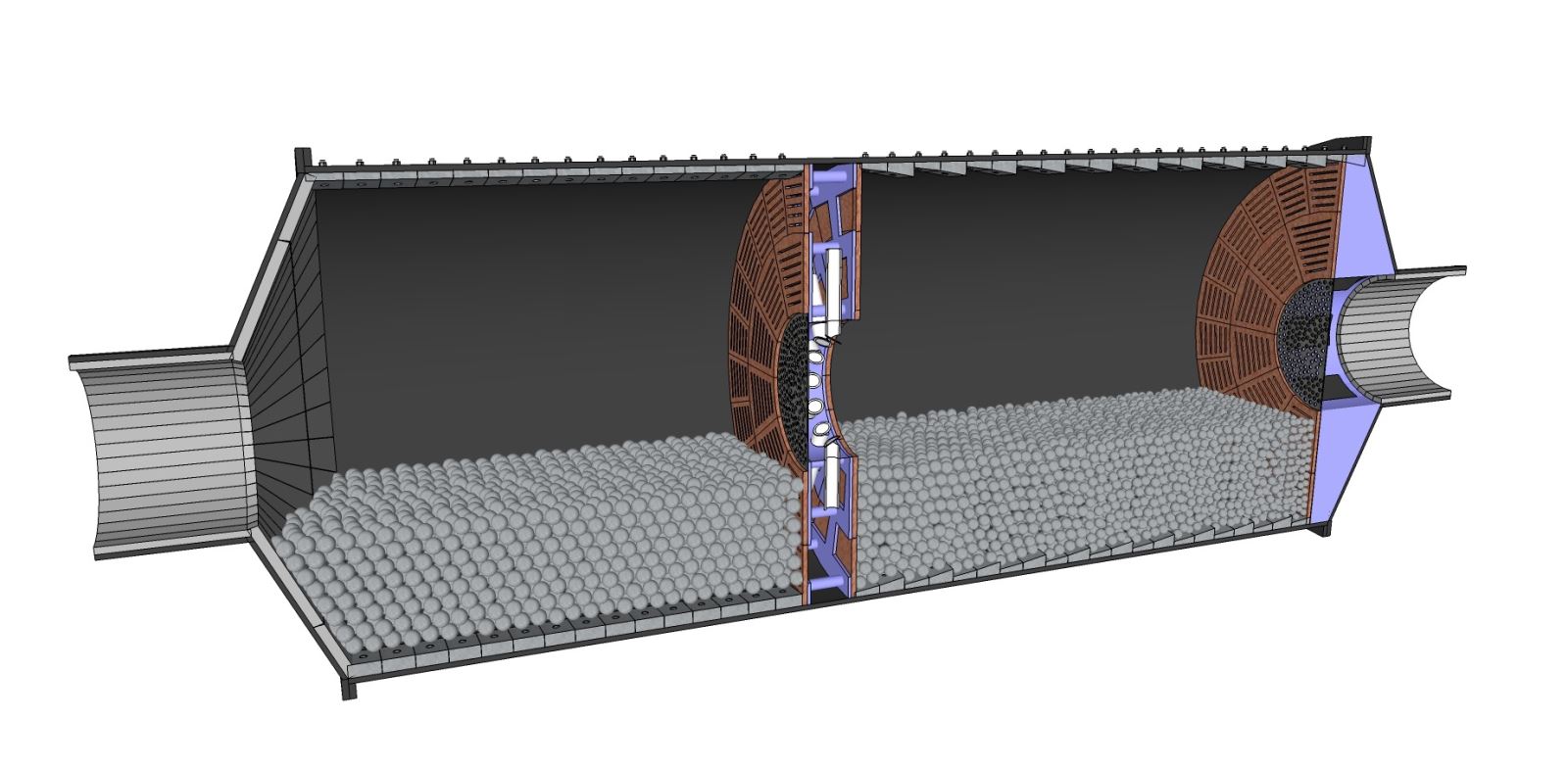

CEMENT INDUSTRY

BALLS :

FTRsteel ONEmax class high chrome balls are especially suitable to be used in the first chambers of raw meal and cement grinding ball mills. ONEmax balls have 16-18% Cr or specifically treated version having 9-11% Cr content. The diameters for first chamber use are 50 - 90 mm.

FTRsteel TWOmax class high chrome balls are similarly proper to charge in to the second chambers of raw meal and cement grinding ball mills. The TWOmax balls contains 10-12% Cr. The diameters for second chamber use are 17 - 50 mm.

CYLPEBS & BALLPEBS :

FTRsteel cylpebs and ballpebs are supplied in the following dimensions;

Cylpebs : 35x35mm, 25x30mm x 25x25mm, 22x28mm, 22x28mm, 22x22mm, 19x19mm and 16x16mm

Ballpebs : 13x16mm, 19x24mm

Please get in touch with us for other dimensions.

Material quality is defined according to customer requirement, then produced.

MINBALLS :

FTRsteel miniballs small diameter grinding balls are unique for special applications in the cement industry. These balls are supplied by FTRsteel in a short time.

General diameters are Ø12mm, Ø10mm, Ø9mm, Ø8mm, Ø7mm and Ø6mm.

Please get in touch with us for other diameters.

Material quality is defined according to customer requirement, then produced.

General specifications - high chrome balls and other grinding media :

►Lesser ball/grinding media wear per ton of ground material,

►Due to homogenious hardness from surface to center and martentisic structure, better griding efficiency in the process is achieved,

►Delivery from stock or short delivery times for most of the diameters and dimensions.