STAINLESS STEEL WEDGE WIRE SCREENS

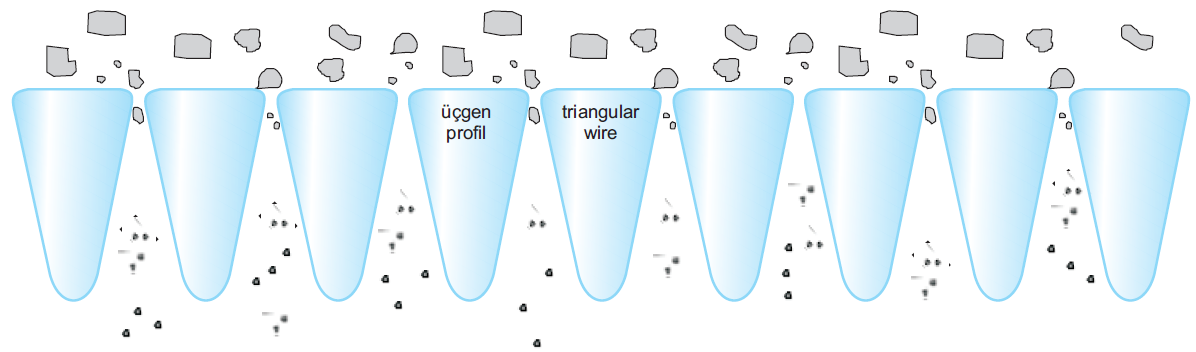

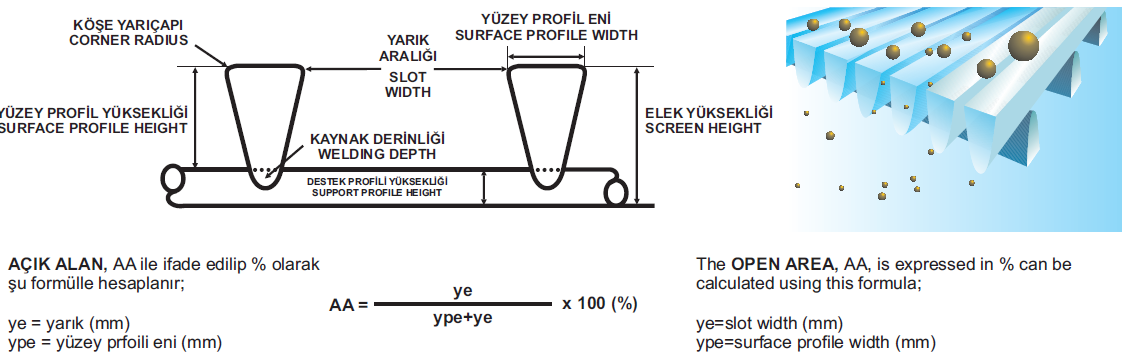

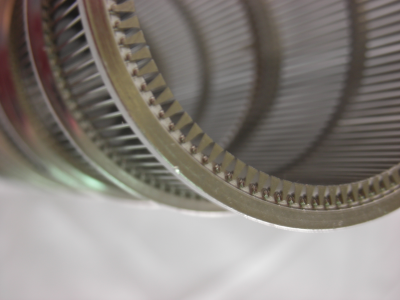

Stainless steel screens are made of triangular profiled wires/rods welded on the supporting rods and used mainly for filtration, classification, separation, dewatering and media retention as well as architectural purposes. The special surface structure enabling the filtration only on the precise surface where the slots are in the form of V-shape, so that the liquid to be filtered passes through the slots smoothly. These screens are also named as ''non-clogging screens'' in the industry.

STAINLESS STEEL WEDGE WIRE SCREENS - MATERIALS AND PROFILES

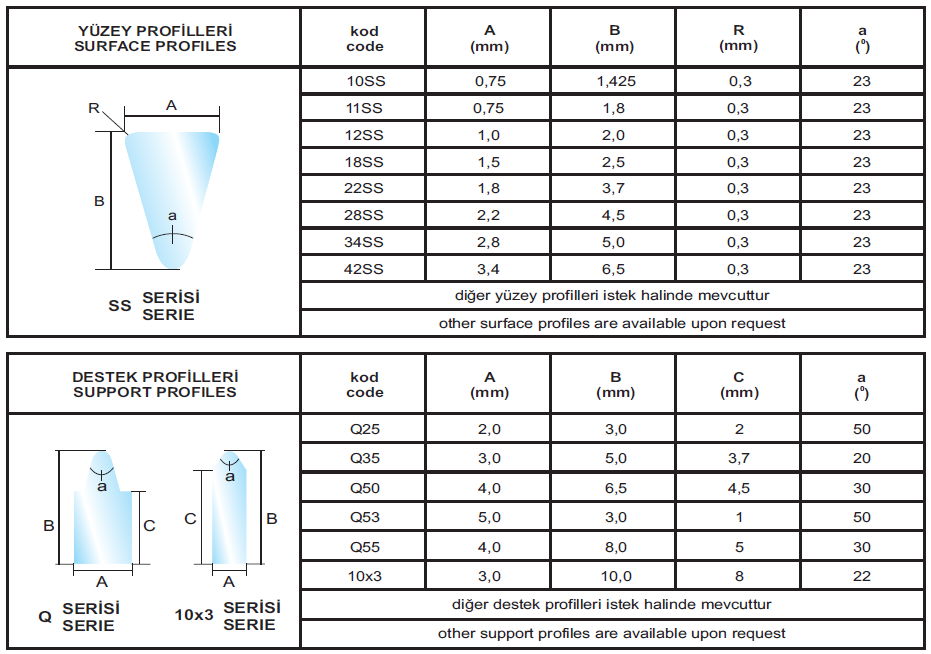

The list of surface and support profiles are given in the table for stainless steel and similar ones. For different profile requirements, please contact us.

TITANIUM GR I I

AISI 430, DIN 1.4016

AISI 304, DIN 1.4301

AISI 316L DIN 1.4435

AISI 316LN DIN 1.4439

URANUS B6 DIN 1.4539

MONEL 400¹ DIN 2.4360

HASTELLOY C276² DIN 2.4819

URANUS 45N (DUPLEX) DIN 1.4462

URANUS 52N (SUPER DUPLEX) DIN 1.4507

254 SMO³ DIN 1.4547

(1) Registered trademark of Inco Alloys

(2) Registered trademark of Haynes International

(3) Registered trademark of Avesta Sheffield AB

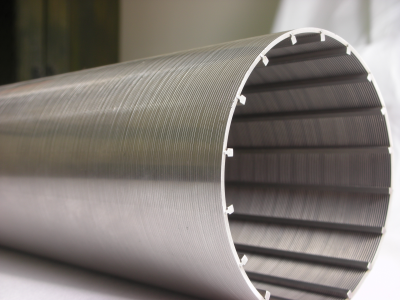

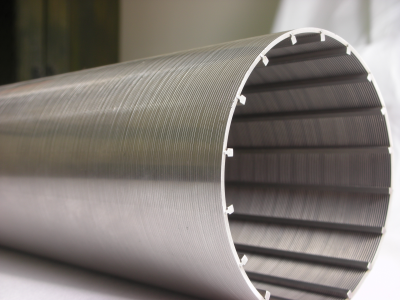

1.-SLOT TUBES

Slot Tubes are manufactured by winding the surface profiles on the support profiles. Each contact points between profiles are specially welded by high-tech welding machines. The end parts of the tubes can also be finished by adapting flanges, threaded connections according to requirements.

GENERAL STRUCTURE:

- Support profiles are always inside

- Support profiles are always longitudinal

- Slots are always circumferential and spiral

- Minimum 10 microns slots

- Flow from in to out (FITO) or flow from out to in (FOTI)

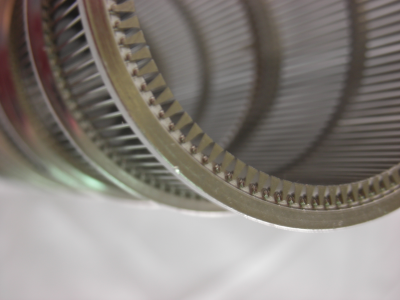

2.-REVERSED SLOT TUBES

Reversed Slot Tubes are generally manufactured by surface profile continuous winding under linear support profiles and completed by hi-tech precise resistance welding on each contact point.

Reversed Slot Tubes are used mainly for flow from in to out (FITO) purposes. Support profiles are always outside and the inner surface is smooth.

GENERAL STRUCTURE:

- Support profiles are always outside

- Support profiles are always longitudinal

- Slots are always circumferential spiral

- Minimum 10 microns slots

- Flow from in to out (FITO)

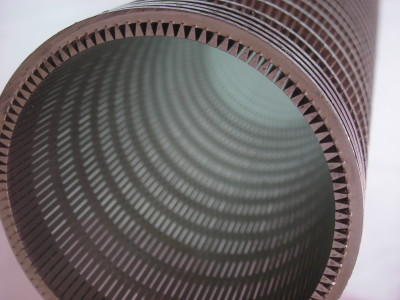

3.-CYLINDERS

Cylinders are manufactured by welding the ring formed support profiles on the longitudinal surface profiles. Each contact point between profiles are welded by a precise welding technology.

The ring-shaped support profiles are always outside Cylinders are suitable for filtering from in to out (FITO). The inner surface is always smooth.

GENERAL STRUCTURE:

- Support profiles are always outside

- Support profiles are always circumferential and ring formed

- Surface profiles are always longitudinal

- Minimum 10 microns slots

- Flow from in to out (FITO)

- Wide range of the lenghts and diameters

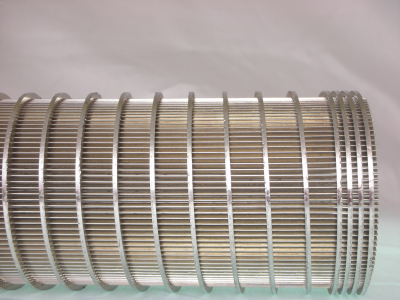

4.-CONTINUOUS CYLINDERS

Continuous Cylinders are manufactured by welding the support profile on the longitudinal surface profiles while the supports are winded continuously on the surface. The sprial formed support profiles are always outside. Continuous cylinders are suitable for filtering from in to out (FITO). The inner surface is always smooth.

GENERAL STRUCTURE:

- Support profiles are always outside

- Support profiles are always circumferential and spiral formed

- Surface profiles are always longitudinal

- Minimum 10 micron slots

- Flow from in to out (FITO)

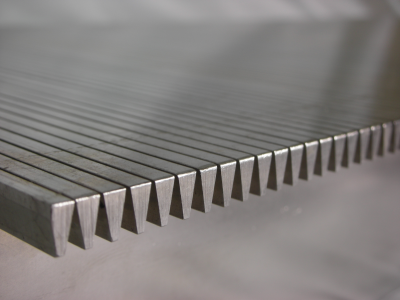

5.-FLAT SCREENS

Flat Screens (also known as welded screens or flat sieves) are manufactured directly the welding of the surface profiles on the support profiles. The pitch of support profiles can be equal or unequal and these can be double layer according to the necessity of the process.

GENERAL STRUCTURE:

- Support profiles are underneath

- Support profiles are always linear

- Surface profiles are always longitudinal

- Minimum 10 micron slots

- Wide range for materials and profiles

6.-BENDED SCREENS

Bended Screens (also known as curved screens, sieve bends or bended sieves) are manufactured by resistance welding of surface profiles on the support profiles. The following final stage is to bend the flat screen over the requested bending angle.

Standard bending degrees are 45°, 60° and 120°. Other angles are also posible upon request.

GENERAL STRUCTURE:

- Support profiles are underneath

- Support profiles are always bended

- Surface profiles are always perpendicular to support profiles

- Minimum 10 micron slots

- Wide range for material and profiles

Stainless steel screens are made of triangular profiled wires/rods welded on the supporting rods and used mainly for filtration, classification, separation, dewatering and media retention as well as architectural purposes. The special surface structure enabling the filtration only on the precise surface where the slots are in the form of V-shape, so that the liquid to be filtered passes through the slots smoothly. These screens are also named as ''non-clogging screens'' in the industry.

Stainless steel screens are made of triangular profiled wires/rods welded on the supporting rods and used mainly for filtration, classification, separation, dewatering and media retention as well as architectural purposes. The special surface structure enabling the filtration only on the precise surface where the slots are in the form of V-shape, so that the liquid to be filtered passes through the slots smoothly. These screens are also named as ''non-clogging screens'' in the industry.